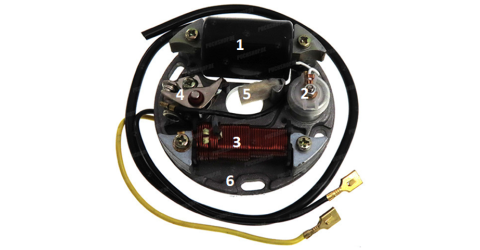

The process of mounting a new axle in a spoke wheel of a Puch Maxi is very easy to do, but it is very important that it is done properly. A new spoke wheel axle comes with a lot of different nuts and washers. Below you can find an example of a front wheel axle:

Here a explanation of the individual parts:

- Axle: There is no thread in the middle; this is the part that sits in the hub. When you mount the axle, make sure that the axle sticks out evenly on both sides of the hub.

- Axle nuts: In this case there are 3 of these nuts, they are all the same. 2 nuts are for securing the wheel later in the front fork. The remaining nut is used to secure the brake anchor plate.

- Thin nuts: 2 of these nuts are used to secure the 2 axle cones (we will go into this later). The remaining thin nut will later be used to secure the counter drive.

- Bearing cones: They press against the balls and hold the balls in place.

- Bearing shells: The shells are pressed into the hub. This is where the balls run in.

- Rings: These 2 rings come around the shaft cones and seal the chamber where the balls enter. This prevents dirt from reaching the balls.

- Distance bush: This small bushing sits between the odometer drive unit and the front fork.

The assembly sequence is explained below:

- Press the 2 bearing shells into the hub (number 5 in the illustration). Make sure they are pressed straight and as far as possible into the hub.

- Fill the bearing shells with ball bearing grease. Gently press the balls into the grease, making sure there are enough balls in the hub. The row should be completely full.

- Slide the axle into the hub, make sure the axle sticks out evenly out on both sides of the hub. Then fit an axle cone on both sides of the axle. Turn them all the way against the balls, hand tightening is sufficient here. There is no need to tighten them with a spanner. Now the axle is centred in the hub and the axle should rotate smoothly.

- Now tighten a thin nut on both sides of the shaft against shaft taper. Tighten the thin nut against the axle cone. Make sure you hold the shaft taper securely while doing this, the shaft taper should not rotate further on the shaft. If both nuts are tight, the shaft should still turn smoothly

- After this, press the 2 thin rings into the bearing shells, now the bearing shells are covered and no dirt can reach them.

- Now the brake torque plate can be slid back onto the hub. This is secured by means of the large nut. On the other side of the hub, the small bushing (number 7 in the photo) can now be fitted. Next, the remaining thin nut is fitted to hold the gearbox in place.

- Now the wheel can be mounted in the front fork, to secure the wheel use the 2 large nuts.