Functioning Puch Maxi E50 clutch

The Puch Maxi with the E50 engine has no gears and is thus called an automatic moped. The clutch causes the moped to move forward from standstill. We call this a centrifugal clutch. As the engine revs up, the clutch segments are pushed outwards, this is called centrifugal force. When the clutch segments go out far enough they hit the clutch housing. The clutch housing starts rotating and then so does the secondary shaft to which the front sprocket is attached.

The original clutch housing rotates over the crankshaft and drives the secondary shaft. On the secondary shaft is the front sprocket. Between the clutch housing and the crankshaft is a bronze bushing. It is important that the clutch housing is mounted free of play on the crankshaft.

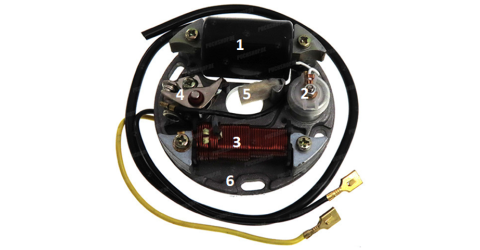

The clutch of an e50 engine contains a few different parts:

- Coupling base plate/base plate

- Clutch segments

- Clutch springs

- Adjusting screws

There are 2 different types of the e50 centrifugal clutch, the run-up and kickstart variant.

The run-up variant has a lining on the back of the base plate. The clutch pressure plate presses against this, causing the crankshaft to start rotating. The clutch is mounted on the crankshaft, so it is automatically driven as well. The start-up variant also has 2 types, a model with 2 clutch segments and a model with 3 clutch segments. The model with 2 segments was often supplied in the older maxi S or N models.

The kickstart variant has no lining on the back of the clutch plate. In a kick-start engine, a pinion is mounted on the crankshaft, making the crankshaft rotate. The clutch is mounted on the crankshaft, so it is automatically driven as well.

The centrifugal clutch can be adjusted so that we can change more or less slip and the engagement moment of the clutch. By slip we mean the moment the clutch shoes touch the clutch housing and the moment the clutch housing starts to rotate. So the engagement moment is the moment the clutch makes the clutch housing rotate.

- More slip: if we want to create more slip, the clutch has to be loosened. This means that the springs must be looser, so the adjusting screws must be turned further out. Now the clutch will engage a little later. This ensures a more gradual engagement. This often applies to faster mopeds that rev more. Because the cylinder often already has a lot of torque, it no longer has to depend entirely on the clutch.

- Less slippage: if we want to create less slippage, the clutch has to be tightened. This means that the springs must be tighter, so the adjusting screws must be screwed in further. Now the clutch will engage sooner and slip less. This ensures faster engagement. This often applies to an original moped. As the cylinder often has a low torque, some torque can be gained with this application.

- Engagement moment: the engagement moment is the moment the clutch segments engage the clutch housing.

Improve/adapt your own clutch

In the webshop, you can find various parts to improve your clutch yourself. The easiest adjustment is to fit different clutch springs. With the use of stronger clutch springs, more torque can be generated. The clutch segments move forcefully inwards or outwards.

A 2nd option is to fit a reinforcement ring on the clutch. It is common on tuned engines for the pins around which the clutch segments hinge to bend. By fitting a reinforcement ring, the pins are connected to each other and cannot bend. To fit the reinforcement ring, holes have to be drilled in the top of the pins, and thread has to be tapped into the holes. Make sure the holes are drilled neatly straight and in the middle.

Custom clutch E50

Various custom clutches can be found in the webshop. These clutches are mainly used for faster mopeds. They are reinforced and have stronger springs. In addition, the clutch segments are often lightened and covered with a different material. This material is a lot more wear-resistant and grips the clutch housing much better. The stronger construction of the clutch allows it to perform better under high revs, so these are always fitted with a reinforcement ring or a reinforcement triangle.

A modified clutch is often used in combination with a modified clutch housing. These clutch housings are made of a different material, which is also more wear-resistant. Also, these clutch housings often contain a needle bearing or an improved bronze bushing. A needle bearing or the improved bronze bushing can withstand high revs better, the material is a lot more wear-resistant.

At high revs, it is also smart to use different clutch oil. This oil is better designed to withstand high temperatures. This is because the disadvantage of a centrifugal clutch is that it generates a lot of heat. The centrifugal force creates a lot of friction and therefore heat.